Interviewed Japanese Glass Sandblasting Artist

This time I interviewed Japanese Glass Sandblasting Artist.

She makes really beautiful glass using sandblast.

Sandblast is a carving technique that blasts sand on the surface of glass.

When I saw her glass I was really impressed with the beautiful design and its color.

I myself visited her work place and saw a big tool for sandblast.

I was interested in how this special glass is made and how she feel or what she think during the work.

So I interviewed her.

I introduce you the interview through Q & A here.

Interview

- How did you come to make glass of sandblast?

I quit my job for taking care of my husband who fell sick and that became a start.

I myself wondered if there is some kind of work which I can do at my house at my pace.

I was reading magazine of business at the book shop and happened to find sandblast in there.

It caught my eye.

I always liked working very much that after thinking I dared to make glass of sandblast. - What is the cat (cat is a motif for some glasses) like?

The cat is quiet and shy and it loves gazing outside. - How do you decide the design?

I always put flashed glass that has not been carved within eyeshot.

I come up with the design from the seasons and things which I heard or watched. - What do you think during the work?

It can not be mass-produced that I keep in mind to express originality of sandblast itself. - Is there any difficulty or hard point during the work?

Masking can be come off if you don’t adjust the pressure, strength, angle, properly.

Fixing is very difficult that it doesn’t fit for sale anymore if you chip the point which should not be chipped.

When it comes to custom-made glass, I need to fine-adjust by checking sample picture over to avoid the gap of image customer holds before I start the work.

※Masking is to protect the parts which should not be carved - What part of the work do you enjoy or feel a sense of accomplishment?

Whenever I peel masking and wash the glass after the blasting, I myself think it is beautiful. ^ ^

When I receive or see happy comment or feedback from the customer, that makes me happier than anything else and that becomes motivation to make good work again. - How long does it take to finish the work?

It takes few days or weeks until I decide the design but once I decide it I think I can make it in a day for one glass. - Could you tell me your thought on the work?

Sandblast has many ways for masking and the price goes up if I invest a good deal of time and effort to it.

It rather becomes craft work than just a product.

But it becomes just another product or an unexciting product if I make it in the easiest way of mass-producing.

It also decreases the value of sandblast itself.

Unfortunately sandblast is still not very famous.

I’d like to make glasses by making use of characteristic of sandblast with reasonable price.

And I’d like more and more people to enjoy glass of sandblast in daily life - May I ask your future prospects?

I’d like to keep making glasses which create a small happiness in everyday life for people as always.

Summary

How was the interview?

Hope you enjoyed it.

Actually made in Japanese product is expensive.

And when it comes to handmade by artist or craftsman in Japan, the price becomes more more expensive.

But I understand it as it takes really time and each works has all the passion of artist and craftsman.

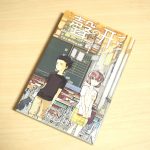

I also buy her work for my webshop JLINK but I also don’t always sell it as it takes time to make it once it sold.

And I also don’t want to put pressure on craftsman or artist for making it hurry.

I don’t usually buy things for myself but when I buy things for myself or for a present for someone else, I decide the thing not only from superficial price but from the quality and the thought of maker in it.

As it becomes special thing to me or to other for good.

This interview became very good experience even to me to know the process and the thought and I might do interview professionals on each field again when I got a chance.